![Arsenopyrite,_Panasqueira_Mine,_Portugal[1] Arsenopyrite,_Panasqueira_Mine,_Portugal[1]](http://tekalloy.com.pa/wp-content/uploads/2015/05/Arsenopyrite_Panasqueira_Mine_Portugal1-428x291.jpg)

Used primarily to alter the morphology of Alumnia inclusion in steel Calcium by converting them to Calcium Aluminates, which have a more spheroid form and a lower melting point. This helps to avoid clogging during the casting process by maintaining liquid inclusions in the steel. Calcium Silicon also can be used to reduce sulfur as Calcium has a high affinity to Sulfur in steel. Other applications for Calcium Silicon are Deoxidation, Chromium and Vanadium recovery and generally to improve mechanical properties of steel ad iron.

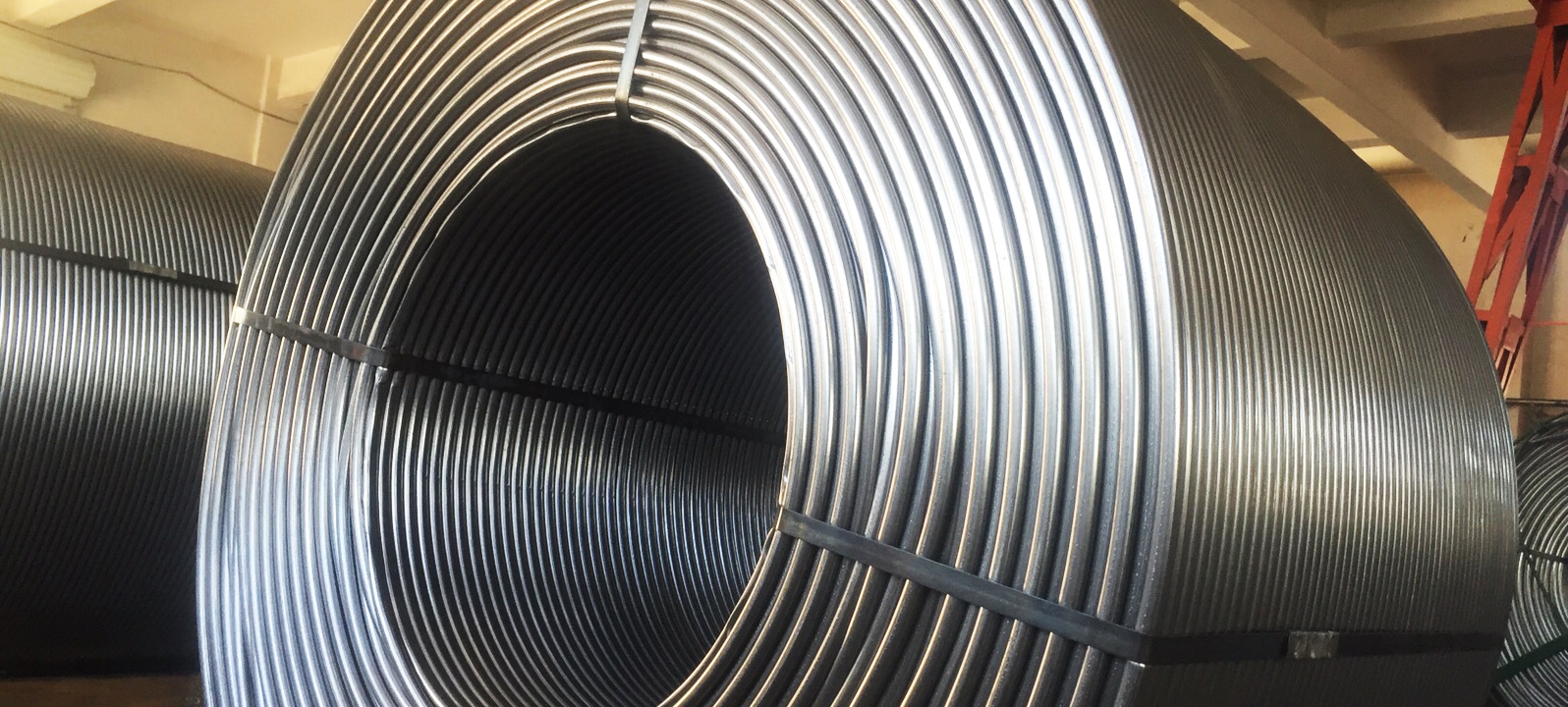

Various Metals and Alloys can be made into Cored Wire which is more an vehicle for the addition of alloys to steel that an end product in itself. Cored wire is made of a hollow steel tube that can be filled with any granular metal or alloys desired. The most common application is using Calcium Silicon, but Tekalloy SA also supplies Carbon, Silicon, Sulfur, as well as Calcium Silicon Cored Wires to the steel industry. The benefit of cored wire is that the material can be injected into the steel ladle very close to the bottom so that the longest possible lifetime if given to the alloy in the wire to do its work in the steel. The steel tube that encased cored wire allows for some limited protection of the wire contents during the injection process and thus, the material inside can react as much of the metal in the ladle as possible. Cored wire increases the efficiency of ladle additions via this method and thus, are a preferred way of adding alloys to steel.

Magnesium is an important alloying element in the Aluminum industry, mainly in the automotive parts an beverage can manufacturing sectors. Primary magnesium is also used in the chemical industry for many applications such as cathodic protection an pyrotechnics, and in the Boron, Lithium, Titanium and Calcium hydrate production. It is also used in the Ductile Iron manufacturing process as a way to convert grey iron to ductile iron, via the modification of graphite flakes into spheres. This modification gives the iron a more ductile nature, hence the name Ductile Iron.

Magnesium Ferro Silicon is one of the best nodularizers in the market due to its low levels of magnesium oxide and high nodularization yield in both �Sandwich� and �In mold� processes. This material is used to modify the graphite flakes in the iron making process, similar to that of Magnesium, but is more passivated and not as violent in the mold, thereby reducing the formation of bubbles and other defects. Magnesium Ferrosilicon also can aid in the nucleation of grain growth an during the solidification process.

Silicon Metal is used for a variety of purposes, such as in the Aluminum Industry for hardening of Aluminum-

World Trade Center, 6st Floor

Office #603, Marbella, Calle 53,

Rep. Panama, Panama

Office : +1 507 223 5185

Fax : +1 507 223 5184

Tekalloy Metals(Tianjin)

Warehouse C, 21 Fuyuan Road,

Wuqing Development

Area, Tianjin High-Tech Industrial Park,

P.R.of CHINA

Zip Code.301700